- MGE's UPS testing and manufacturing facility

- MGE recently installed new equipment to automatically test the UPSs it sends out to customers. Check out these photos of the testing bays and other areas of the MGE manufacturing facility in Costa Mesa, Calif. Photos by Mark Fontecchio.

-

1

-

The testing area for MGE's Galaxy 3000 and Galaxy 4000 line of UPSs. This is on the second floor of the manufacturing facility. The testing is done just yards away from the manufacturing.

-

-

2

-

From left to right: An MGE UPS (with its door open), the UPS testing equipment (with all the cables going into it), and the station where all of the testing data goes.

-

-

3

-

Larger UPS systems from MGE that are being tested. These behemoths, from the company's EPS line, are on the ground floor of the facility. Upper floors wouldn't be able to handle their weight, which can get as high as seven tons without the batteries loaded in.

-

-

4

-

Another testing area, for smaller UPS systems from MGE's EPS line. This is also where MGE can do burn-in tests for customers to ensure that they're "broken in" and working properly.

-

-

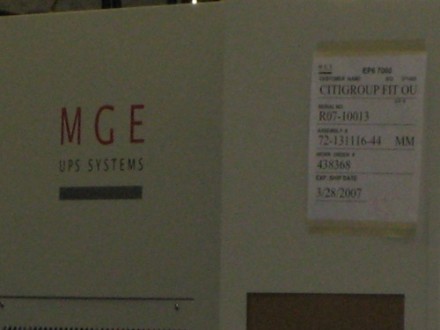

5

-

If you look closely to the right, it seems as if this UPS will eventually be going to Citigroup.

-

-

6

-

This is the training area. John Goosseff, MGE's three-phase product marketing manager, said that new hires coming in will earn their stripes on these UPSs, which are often old pieces of equipment that MGE no longer manufacturers but which are still out in the field.

-

-

7

-

Another customer-testing area (as you can see, we weren't able to get inside). Goosseff explained that if a customer is having issues with their UPS system, and a field engineer can't figure it out either, the equipment will often get shipped back to Costa Mesa, where MGE will run its own tests on the UPSs to determine if it's an equipment malfunction or user error.

-

-

8

-

In addition to the training area, which is downstairs, MGE has a whole classroom setting on the second floor for trainees. New hires sit through classes, where they're introduced to old UPSs like these to get an idea of how they work.

-

-

9

-

Goosseff points to one of MGE's static transfer switch products.

-

-

10

-

Here's a look inside an MGE UPS (either the Galaxy 3000 or 4000) loaded up with backup batteries, which you can see to the right.

-